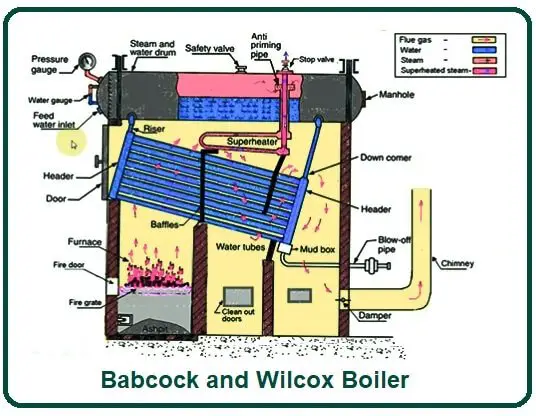

Advantages of Babcock and Wilcox Boilerįollowing are the advantages of Babcock and Wilcox boiler: Blow-off cock is provided for the periodical removal of mud and sediments collected in the mud box. The stop valve and steam safety valve are mounted on the upper side of the drum. The water level indicator and pressure gauge are attached to the boiler at its left end. The boiler is fitted with the necessary mountings for safe operation. Steam is taken from the steam space through tubes to the superheater. The circulation of water is maintained by convective currents and is known as “nature circulation”. The water from the drum comes down through the down header into the water tubes.Ĭontinuous circulation of water from the drum to the water tubes and vice versa is thus maintained. Steam, which lighter is being collected in the upper part of the drum. Here the steam and water are distributed in the drum. Water rises into the drum through the uptake header. The portion of the water tubes, which is just above the furnace, is heated comparatively to a higher temperature than the rest of it. The exhaust gases leave the atmosphere through the chimney. The baffles deflect the flue gases and hence the flue gases travel in a zig-zag manner over the water tubes and along with the superheater. The hot exhaust gases expand upward and pass across the left side of the water tubes. Working of Babcock and Wilcox BoilerĬoal is fed to the grate through the fire door and is burnt. It is used to control the flow of steam from the boiler to the main steam pipe and to shut off the steam completely when required. The superheater is used to increase the temperature of saturated steam without raising its pressure. SuperheaterĪ superheater is the main part of a steam-generating unit. This a device attached to the steam chest for preventing explosions due to excessive internal pressure of steam. Pressure GaugeĪ pressure gauge is used to measure the pressure of the steam inside the boiler drum. It is an important fitting, which indicates the water level inside the boiler drum to an observer. The following are the several boiler mounting and accessories used in this type of boiler: Read also: Boiler Mountings and Accessories: Types, and Their Working Boiler Mounting and Accessories of Babcock and Wilcox Boiler The dampers are operated by a chain that passes over a pulley to the front of a boiler to regulate the draught. The furnace is placed under the uptake header. It is employed to fill water in the drum. Mud BoxĪ mud box is provided with each down take header and the mud, that is settled down is removed. It is a platform, in which the solid fuel (coal) is burnt. It is applied to burn solid fuel in the furnace. Baffle plates are provided to deflect hot flue gases. It causes hot gases to move upwards and downwards and again upwards before leaving the chimney. The Baffle plates are present within the water tubes. Due to its inclination, the water tubes are not completely filled with water, and water and steam are easily separated. The water tubes (10 cm diameter) are inclined to the horizontal and connect the uptake header to the down take header. These are the tubes in which water passes and changes into steam. It transmits the steam from water tubes to the drum. It is present at the front end of the boiler and is attached to the front end of the drum.

This is present at the rear end of the boiler and joins the water tubes to the rear end of the drum. It is connected by a short tube with an uptake header or riser at the back end. It is a horizontal axis drum containing water and steam. Read also: Steam Boilers: Parts, Types, Classification, Advantages, Application, and More 1. Parts of Babcock and Wilcox Boilerįollowing are the important parts of Babcock and Wilcox Boiler. The dampers are used to regulate the draught and are operated by a chain and a pulley. The firebricks baffle wall deflected the hot gases and help the hot gases to leave the chimney. There is a slow-moving chain on which coal is fed from the hopper.

0 kommentar(er)

0 kommentar(er)