- POST PROCESSOR POWERMILL CONFIGURATION FULL

- POST PROCESSOR POWERMILL CONFIGURATION VERIFICATION

- POST PROCESSOR POWERMILL CONFIGURATION SOFTWARE

- POST PROCESSOR POWERMILL CONFIGURATION CODE

- POST PROCESSOR POWERMILL CONFIGURATION LICENSE

With the TruePath and Powermill plug-in users can easily export the Geometry files, Tooling Database and CL data.

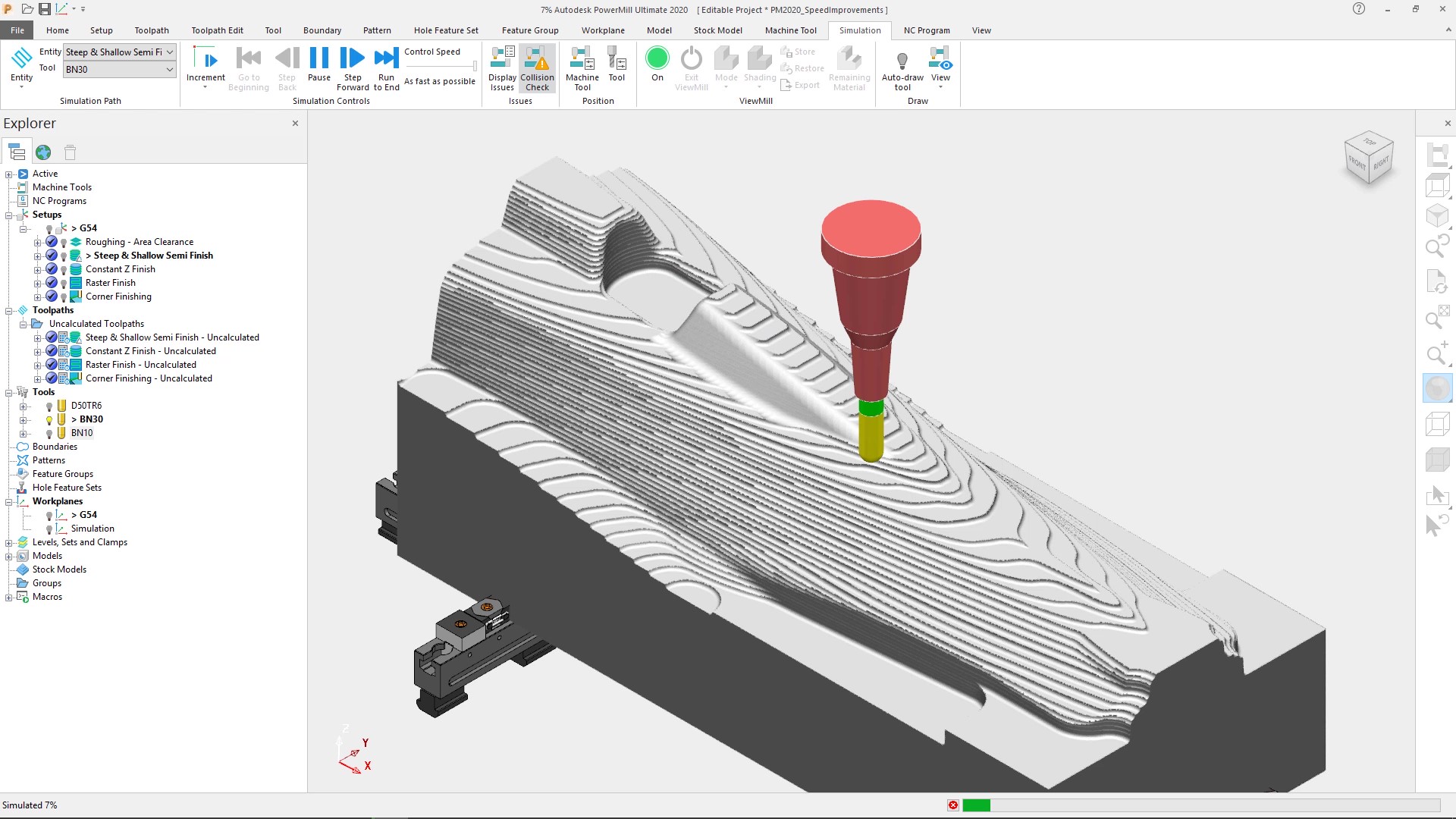

Collision detection and material removal simulation takes the guess work out of the process by providing an accurate representation of what will happen on the machine.

TruePath bridges the gap between PowerMILL and your milling machine. More than 15,000 organizations use PowerMILL worldwide. To define a default postprocessor option file to be used whenever a new nc program is created follow these steps: Right click object type NC Program.

POST PROCESSOR POWERMILL CONFIGURATION SOFTWARE

The software can be used in a range of different engineering industries to determine optimal tool paths to reduce time and manufacturing costs as well as reduce tool loads and produce smooth surface finishes. PowerMILL is a 3D CAM solution that runs on Microsoft Windows for the programming of tool paths for 2 to 5 axis CNC Milling machines. Autodesk PowerMill provides tools to make efficient 5-axis milling a reality. As part complexity has increased so have the demands on CAM software to create safe and reliable milling programs. Today’s parts are more complex than ever, often containing features and details that cannot be produced using 3-axis milling alone. Autodesk makes software for people who make things, whether its architecture, engineering, or manufacturing, Autodesk has a software for you. Powermill is the fourth CAM system from Autodesk compatible with CAMplete TruePath. Since 1982, Autodesk has grown into a multinational software company spanning across a wide range of industries. The versatile and flexible software package offers the end user everything needed to analyze and simulate multi-axis tool paths in a 3D environment.

POST PROCESSOR POWERMILL CONFIGURATION VERIFICATION

TruePath’s software suite also includes verification and simulation tools dedicated to 5-axis machining centers. Sources: Press materials received from the company and additional information gleaned from the company’s website.CAMplete TruePath software offers more than just serving as a PowerMill Post processor. To learn more about this product, visit SolidCAD’s website or join SolidCAD for a webinar that will showcase MAKE Productivity on Tuesday, September 21 at 3:00 p.m.

POST PROCESSOR POWERMILL CONFIGURATION FULL

While MAKE Productivity and PowerMill Ultimate will have all the standard features plus machine simulation, tool change and laser cycle validation, and access to full five-axis programming with automatic collision avoidance, robot programming, electrode programming, hybrid manufacturing and more.

POST PROCESSOR POWERMILL CONFIGURATION CODE

With MAKE Productivity and PowerMill Standard, users will have the ability to rapidly create NC code for high-speed three-axis machining, 3+2 programming, 2.5D milling, turning and toolpath safety verification. SolidCAD offers two versions of the product that work with Autodesk’s Standard or Ultimate versions of PowerMill. “MAKE Productivity is providing the enhancements and value-added tools for which our customers have been requesting, and we are pleased to have developed this collaboratively to suit these needs.” “SolidCAD is responding to our customer’s needs for a robust and customizable solution to automate their complex CAM programming processes,” says Robert Kobielski, sales manager of Advanced Manufacturing at SolidCAD.

POST PROCESSOR POWERMILL CONFIGURATION LICENSE

Users can now optimize after-hours license use by creating a batch calculation queue for “lights-out” calculation of multiple projects. Paired with Autodesk’s PowerMill Ultimate, this product allows for simultaneous five-axis programming automation and enhanced machine simulation of NC programs, tool changes and laser cycles. MAKE Productivity can allow users to automate 90%-100% of their complex finish programming by using the guided workflow. MAKE Productivity for PowerMill is a tool to boost CAM programming productivity, provide staffing flexibility to overcome skilled labor shortages, and optimize machine scheduling and use by programming well ahead of runtime.Įquipped with a suite of calculators and tools for daily programming, MAKE Productivity provides capabilities for automating simple and complex multi-axis manufacturing processes, along with “on-demand” digital learning modules and training content for the user’s self-directed learning plans. SolidCAD, a Canada-based professional services company and Autodesk Platinum Partner, launches its newest product, MAKE Productivity.

0 kommentar(er)

0 kommentar(er)